china bmc mold

1. Product Overview

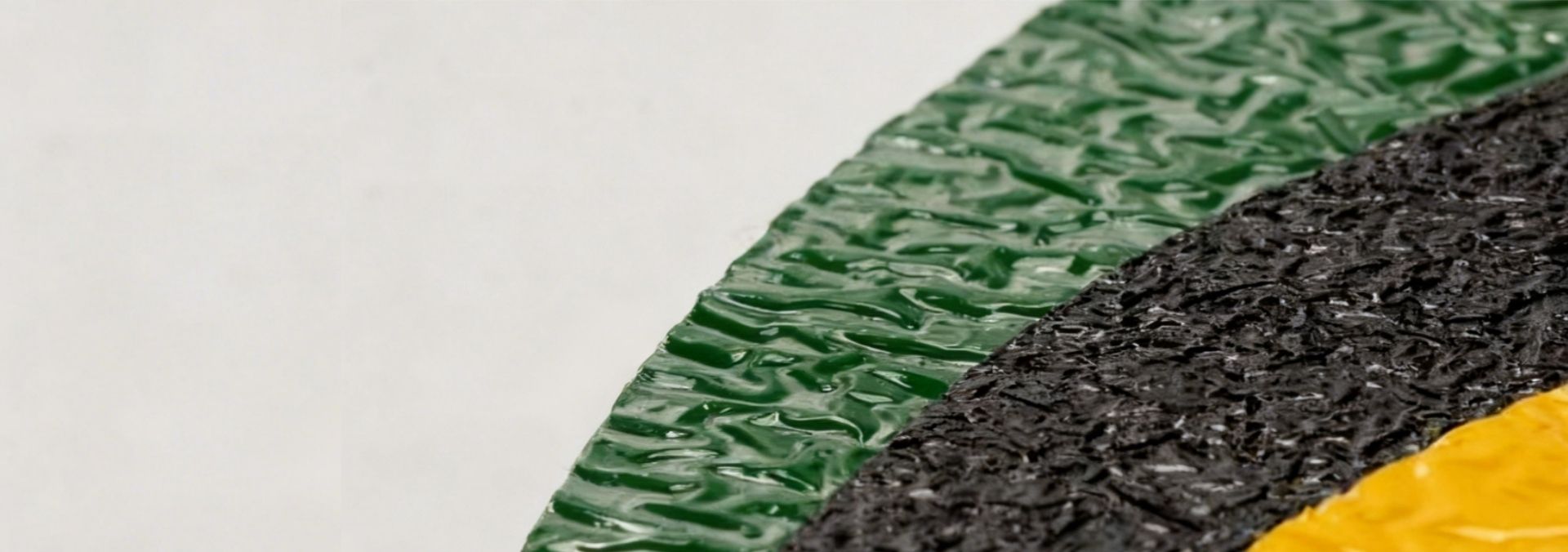

Chinyo, a China-based manufacturer specializing in china bmc mold, produces high-precision compression molded plastic components. These parts are crafted through advanced china bmc mold processes—where heated plastic materials are pressed into custom molds—to create durable, consistent components tailored for industrial use. Unlike generic molded parts, Chinyo’s products are engineered to align with global B2B procurement standards, making them a go-to choice for international clients seeking China-sourced industrial solutions.

2. Core Value &Technological Advantages

The product’s core strength lies in reliability, driven by two key technological features. First, Chinyo uses automated china bmc mold systems with ±1℃ temperature control (a feature that minimizes material waste). This ensures a defect rate of less than 0.5% (an advantage), directly reducing clients’production downtime and replacement costs (user benefit). Second, all components use ISO 9001-certified raw materials (e.g., high-grade PP and PC). This boosts wear and corrosion resistance (an advantage), extending the product’s lifespan by 30% compared to standard molded parts (user benefit) and lowering long-term procurement expenses.

3. Core Application Scenarios

Chinyo’s compression molded plastic components serve 4 key industrial sectors, each with targeted suitability:

Automotive:Ideal for under-hood sensor housings, as they withstand temperatures up to 150℃—meeting strict automotive industry durability requirements.

Electronics:Perfect for circuit board enclosures, thanks to ±0.02mm molding tolerances that shield internal components from dust and moisture.

Medical Devices:Suitable for non-toxic instrument handles, as they comply with FDA and CE medical-grade standards to ensure patient safety.

Industrial Machinery:Fits heavy-duty gear covers, leveraging 15kJ/m²impact strength to resist vibrations during operation.

4. Core Parameter Overview

| Parameter Category | Key Details |

|---|---|

| Size Range | 5mm –500mm (customizable for specific B2B project needs) |

| Material Type | PP, PC, PBT, nylon (all ISO 9001-certified for industrial use) |

| Performance Metrics | Temperature resistance:-40℃ to 150℃;Tolerance:±0.02mm;Impact strength:15kJ/m² |

| Compliance Certifications | ISO 9001, FDA, CE, RoHS (meets global B2B procurement compliance demands) |

5. B2B Procurement FAQ &Call to Action

FAQ (Focused on Procurement Needs)

Q:Can Chinyo customize components for our unique industrial design?

A:Yes—we offer end-to-end customization (material, size, mold design) with a 7-10 day sample lead time, ensuring alignment with your project timeline.Q:What is the MOQ for bulk orders?

A:Our MOQ starts at 500 units, with discounted pricing for orders over 10,000 units to support your production scalability.Q:How do you guarantee quality for mass production?

A:We conduct 100% automated optical inspection post-production and provide a 12-month warranty, addressing batch consistency concerns.

Call to Action

We are Chinese—Chinyo brings 15 years of china bmc mold expertise to your B2B procurement. Our China-based factory combines cost-effectiveness with global quality standards, delivering components that solve your industrial reliability needs. Contact our sales team today for a personalized quote and partner with a trusted Chinese manufacturer.