china moulding compound

About china moulding compound

Chinyo a flagship enterprise in the china moulding compound sector, is dedicated to the R&D, production, and sales of high-performance BMC composites. Our china moulding compound—a thermosetting composite made of resin, glass fiber, and fillers—boasts outstanding heat resistance, electrical insulation, and dimensional stability, core traits that set China’s BMC manufacturing apart from global peers.

As a key player in China’s composite material industry, we have obtained ISO and CE certifications, supplying custom BMC solutions to automotive, rail transit, medical, and electrical industries across Europe, Asia, and North America, solidifying China’s position as a leading BMC producer worldwide.

Our Core China SMC Product List

Car Lamps Components

Core Material: china moulding compound, low-shrinkage polyester BMC

Selling Points: UV resistance, anti-yellowing, high light transmittance

Applicable Scope: Car headlights, taillights, turn signals

Process: Compression moulding, optical coating

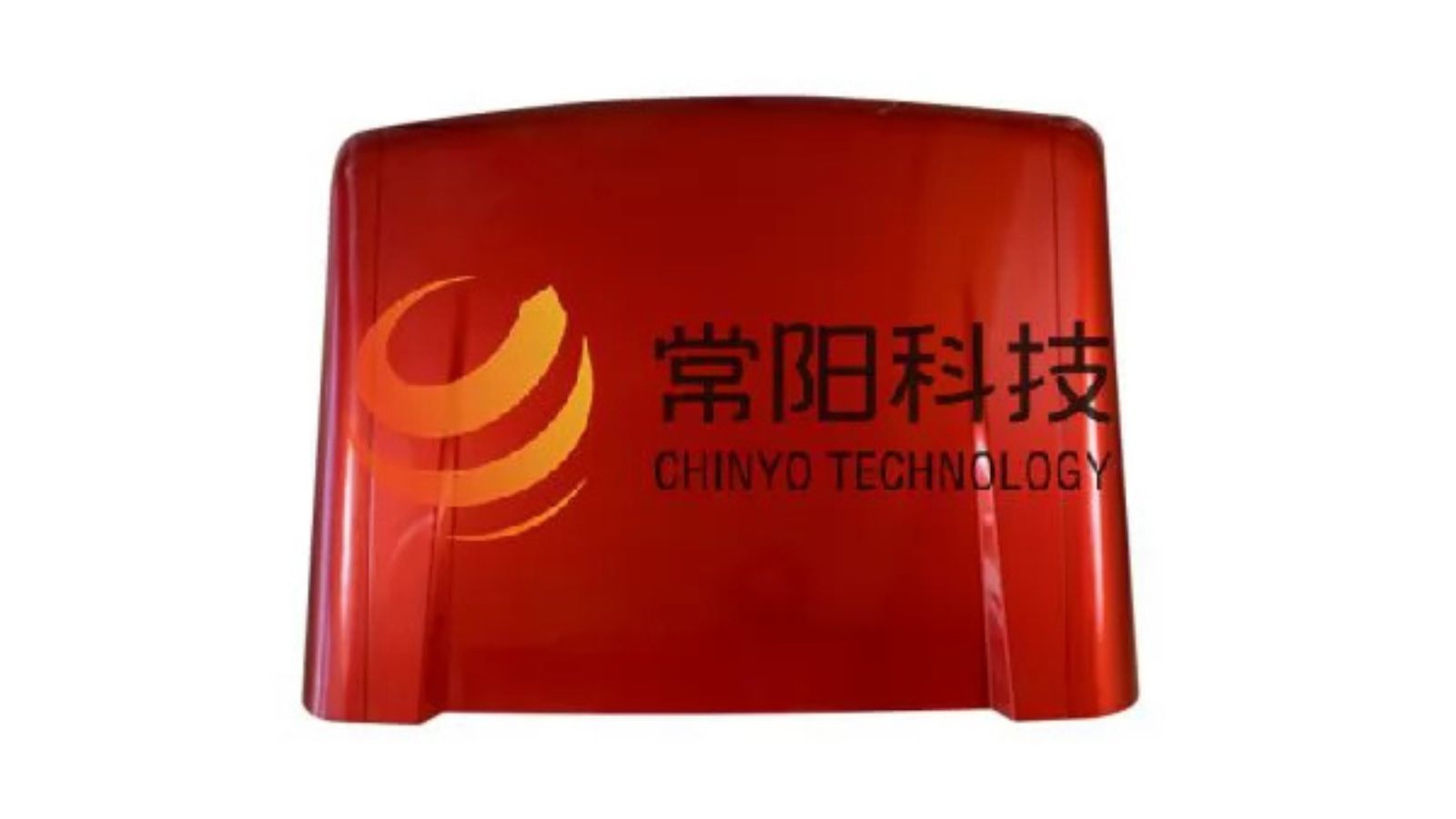

EV Car Battery Cover

Core Material: Flame-retardant china moulding compound

Selling Points: Electrical insulation, explosion-proof, high-temperature resistance

Applicable Scope: EV lithium battery packs for sedans/SUVs

Process: High-pressure moulding, IP67 waterproof treatment

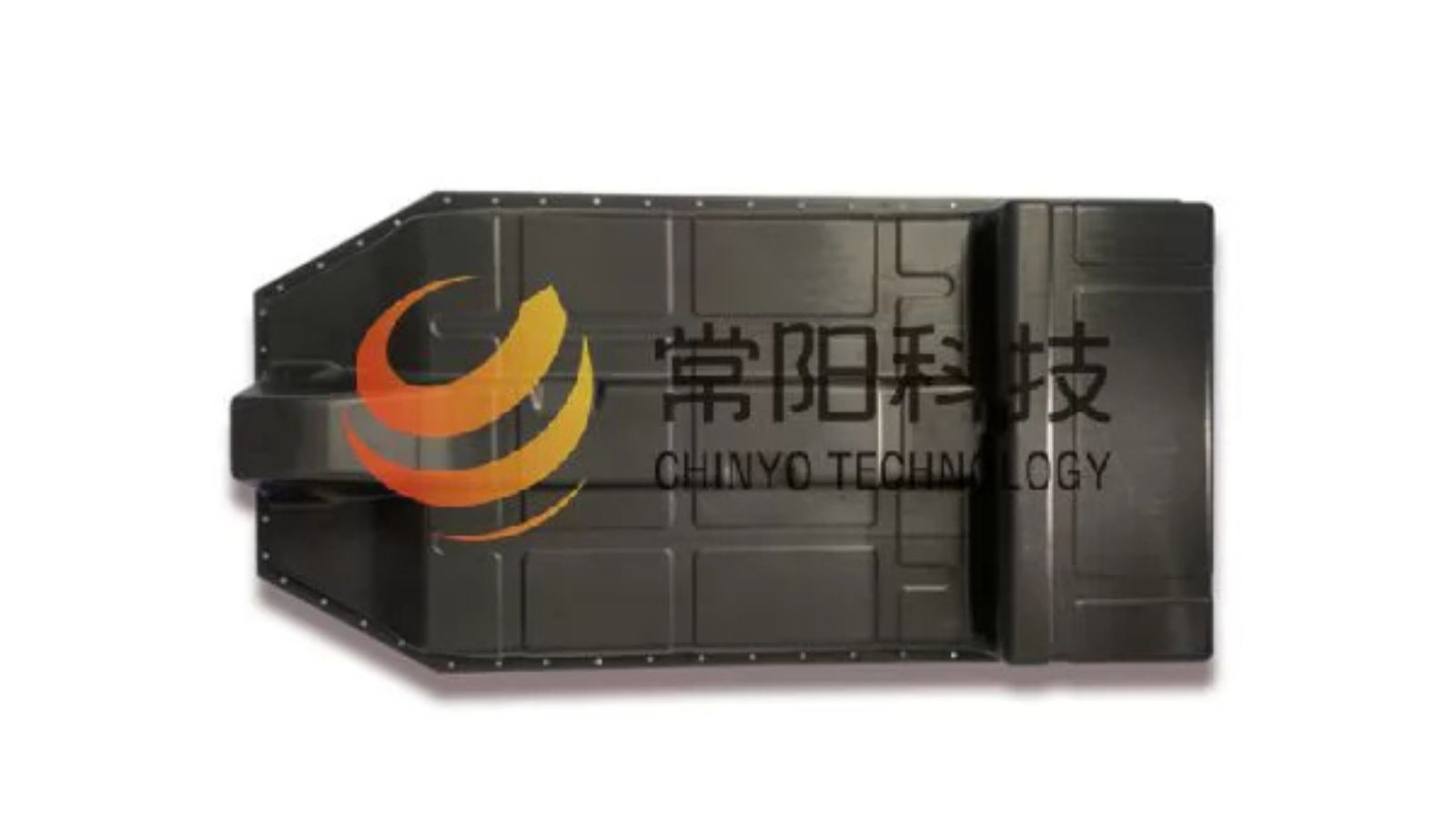

High Speed Train Internal Parts

Core Material: Low-odor china moulding compound, eco-friendly BMC

Selling Points: Fire-retardant, noise reduction, easy maintenance

Applicable Scope: Train air vents, switch panels, storage liners

Process: Low-pressure moulding, texture embossing

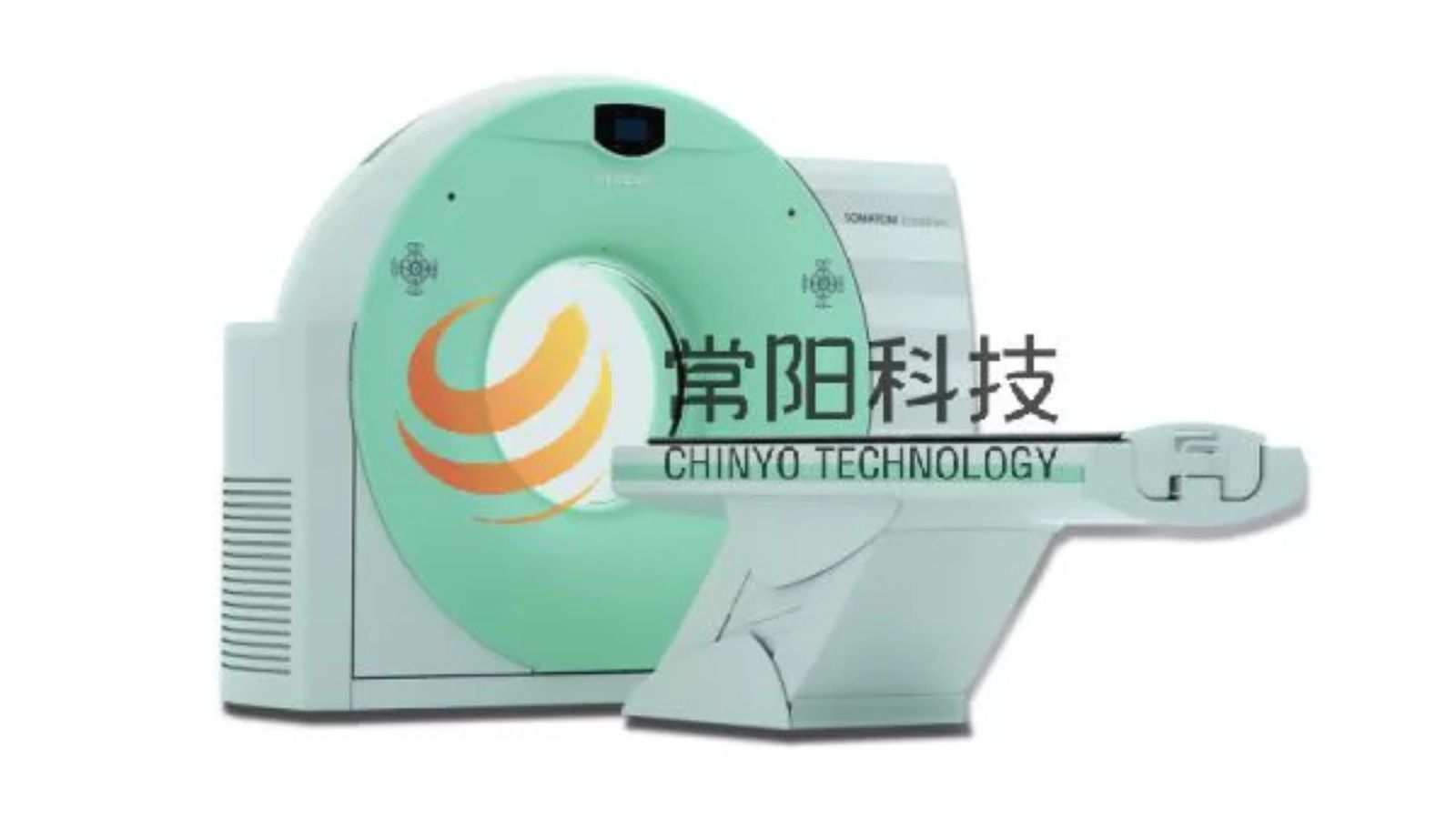

CT Machine Enclosures

Core Material: Radiation-shielding china moulding compound

Selling Points: Radiation protection, antibacterial, rigid strength

Applicable Scope: CT/MRI equipment outer casings

Process: Precision moulding, radiation leakage detection

Applications of china moulding compound Products

Automotive Lighting

Make car lamps components with china moulding compound for anti-yellowing.

New Energy Vehicles

Produce EV battery covers to ensure battery insulation and safety.

High-Speed Rail

Fabricate internal parts to meet train fire-retardant and noise requirements.

Medical Equipment

Manufacture CT enclosures with radiation-shielding BMC for hospitals.

Electrical Engineering

Create insulation components for high-voltage switchgear with BMC.

Building Industry

Install BMC sealing parts for waterproof and corrosion-resistant construction.

Key Advantages of china moulding compound

Superior Material Performance

china moulding compound delivers superior electrical insulation and heat resistance.

Precision Moulding

BMC’s precision moulding ensures consistent dimensions for mass production needs.

Cost-Effective

China-made BMC is cost-effective vs imported composites with equivalent performance.