china sheet molding compound manufacturers

1. An Overview of Chinyo’s china sheet molding compound manufacturers

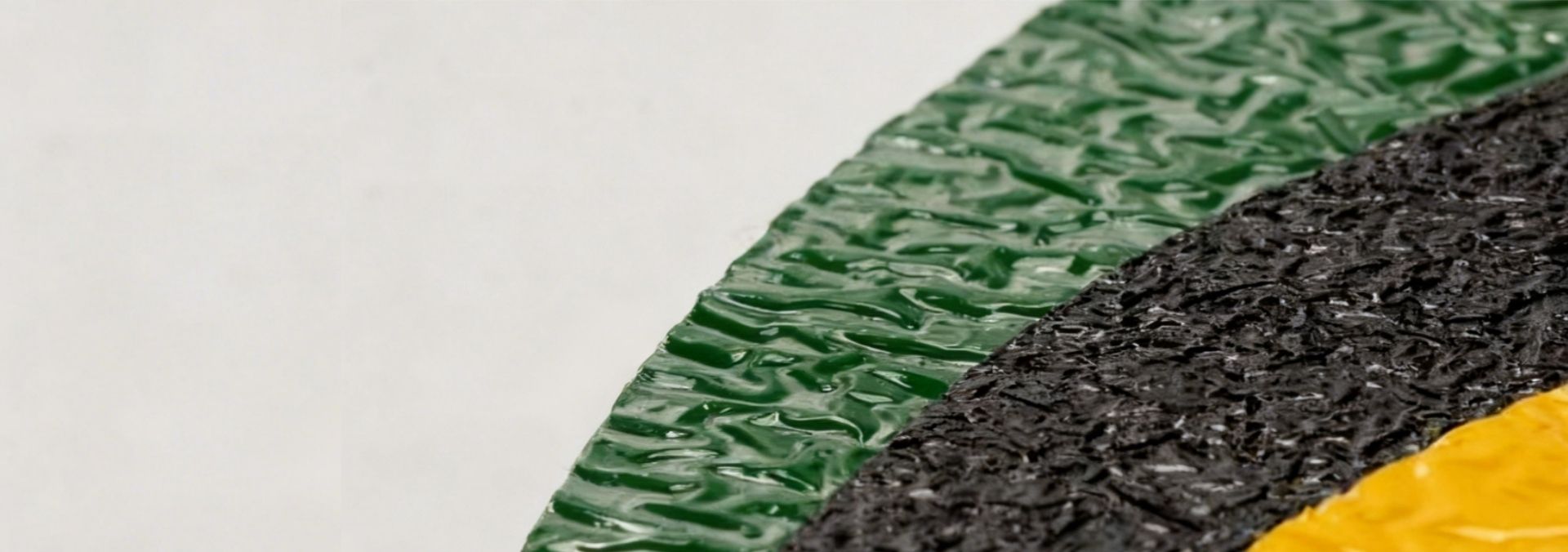

china sheet molding compound manufacturers are composite materials widely used in industrial sectors for their excellent mechanical and chemical properties, and Chinyo has emerged as a trusted provider of these solutions in China. Our china sheet molding compound manufacturers are manufactured using advanced mixing and molding processes, combining fiberglass, resin, and additives to create components that balance strength, lightweight design, and corrosion resistance. Unlike traditional metal or plastic parts, Chinyo’s china sheet molding compound manufacturers offer better dimensional stability, making them suitable for long-term use in harsh environments. For B2B buyers, this means accessing reliable, consistent products that align with global industrial requirements, directly sourced from a leading manufacturer in China.

2. Core Value and Technological Advantages of Chinyo’s china sheet molding compound manufacturers

Chinyo’s china sheet molding compound manufacturers stand out for their targeted technological features that translate to tangible advantages for users. A key feature is our proprietary resin formulation, which enhances the products’heat resistance (up to 150°C continuous use) –this advantage means china sheet molding compound manufacturers from Chinyo can operate stably in high-temperature industrial settings, reducing the risk of component failure and unplanned downtime for buyers. Another feature is the high fiberglass content (30-40% by weight) in our SMC, which boosts impact resistance by 40% compared to standard SMC products on the market. For B2B users, this advantage translates to a 50% longer service life of parts, cutting down on replacement costs and maintenance efforts. Additionally, Chinyo’s china sheet molding compound manufacturers are engineered for low water absorption (less than 0.2%), an advantage that ensures long-term performance in humid or outdoor environments, addressing a common pain point for industries like new energy and construction.

3. Application Scenarios:Chinyo’s china sheet molding compound manufacturers Across Key Industries

Chinyo’s china sheet molding compound manufacturers are versatile, fitting seamlessly into multiple core industries, each with unique needs that our solutions address.

In the new energy industry (e.g., wind power and solar energy), china sheet molding compound manufacturers like wind turbine nacelle covers and solar panel frames excel due to their corrosion resistance and UV stability. These properties protect critical new energy equipment from outdoor elements, ensuring consistent energy generation –a must for B2B clients in renewable energy who prioritize long-term operational reliability.

For the automotive industry, Chinyo’s china sheet molding compound manufacturers (such as battery housings for electric vehicles) offer lightweight design (20% lighter than aluminum alternatives) without compromising strength. This helps automakers reduce vehicle weight, improve energy efficiency, and meet strict emissions standards, a key requirement for B2B automotive suppliers seeking to support EV transition.

In the construction industry, our china sheet molding compound manufacturers (e.g., electrical enclosures and pipe supports) provide excellent insulation and fire resistance (UL94 V-0 rating). This makes them ideal for building infrastructure, as they enhance safety and comply with China’s national construction codes, solving the problem of fire hazards associated with traditional plastic enclosures for B2B construction firms.

The electrical equipment industry also benefits from Chinyo’s china sheet molding compound manufacturers, such as high-voltage switchgear components. Their excellent electrical insulation properties (dielectric strength of 20 kV/mm) prevent electrical leakage, ensuring the safety and stability of power distribution systems –a critical need for B2B electrical equipment manufacturers aiming to meet international safety standards.

4. Core Parameter Overview of Chinyo’s china sheet molding compound manufacturers

The following table outlines key parameters of Chinyo’s china sheet molding compound manufacturers, categorized for clarity to help B2B buyers evaluate suitability for their needs:

| Parameter Category | Core Specifications (china sheet molding compound manufacturers by Chinyo) |

|---|---|

| Size Range | Customizable from 100mm×100mm (small components) to 2000mm×3000mm (large structural parts);thickness:2mm-50mm |

| Material Composition | Resin matrix (unsaturated polyester resin), fiberglass (30-40% content), additives (anti-UV, flame retardant) |

| Performance | - Heat resistance:Continuous use at ≤150°C - Impact resistance:40% higher than standard SMC - Water absorption:≤0.2% - Dielectric strength:20 kV/mm |

| Compliance Certification | - China:GB/T 15568-2008 (SMC molding compounds) - International:ISO 14411, UL94 V-0 |

5. FAQ for B2B Procurement of china sheet molding compound manufacturers &Call to Action

Common B2B Procurement Questions About Chinyo’s china sheet molding compound manufacturers

Q:What is the minimum order quantity (MOQ) for Chinyo’s china sheet molding compound manufacturers, and can customization be supported?

A:Our MOQ for standard china sheet molding compound manufacturers is 500 units, while customized parts (e.g., unique sizes or colors) have an MOQ of 1000 units. We work closely with B2B clients to adjust specifications based on their production needs, ensuring the final product fits their assembly lines.Q:How long is the lead time for bulk orders of china sheet molding compound manufacturers, and is there a guarantee for on-time delivery?

A:For standard products, lead time is 2-3 weeks;customized china sheet molding compound manufacturers take 4-6 weeks. We maintain a 98% on-time delivery rate, supported by our 3 production bases in China, which allows us to scale output based on client demand.Q:What quality assurance measures are in place for Chinyo’s china sheet molding compound manufacturers, and do you provide test reports?

A:Every batch of china sheet molding compound manufacturers undergoes 100% inspection (including dimensional accuracy and performance testing) before shipment. We provide detailed test reports (compliant with GB and ISO standards) to B2B buyers, ensuring transparency and confidence in product quality.

Call to Action

We are Chinese manufacturer Chinyo, dedicated to delivering high-quality china sheet molding compound manufacturers that solve your industrial challenges. Whether you need standard components or customized solutions, our team is ready to collaborate with your business. Contact us today to discuss your procurement needs and receive a tailored quote –let Chinyo’s expertise in china sheet molding compound manufacturers support your operational success.