INDUSTRIAL APPLICATIONS

CHINYO’s composite materials are reshaping industries by replacing conventional materials. Offering unmatched strength, lightweight properties, and durability, we’re driving innovation in automotive, construction, and energy, setting new benchmarks for performance and sustainability.

Request Sample

Application Areas

Automotive

Lightweight, high-strength components for both interior and exterior applications, reducing vehicle weight while maintaining structural integrity and safety standards.

Our Products Used:

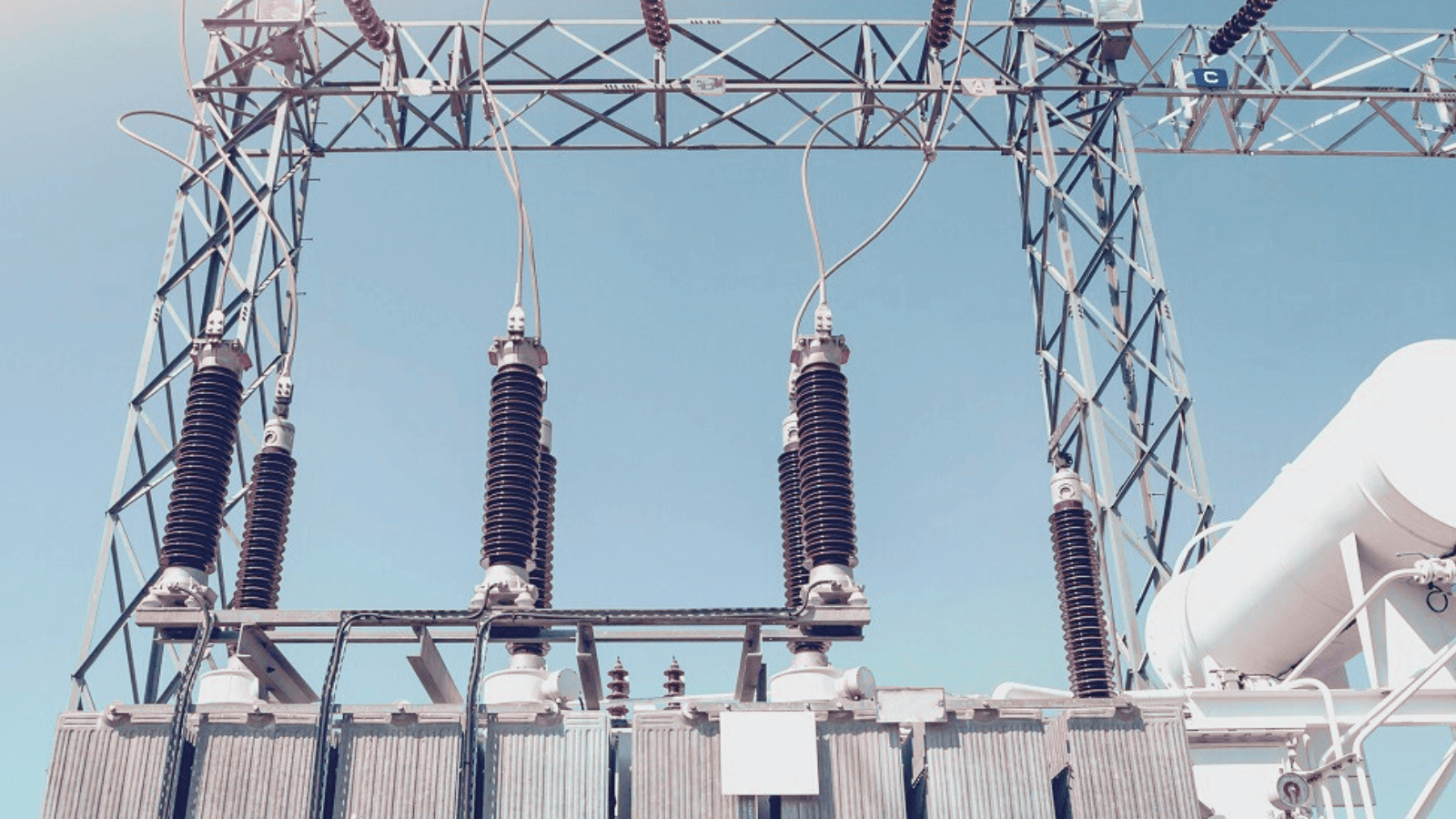

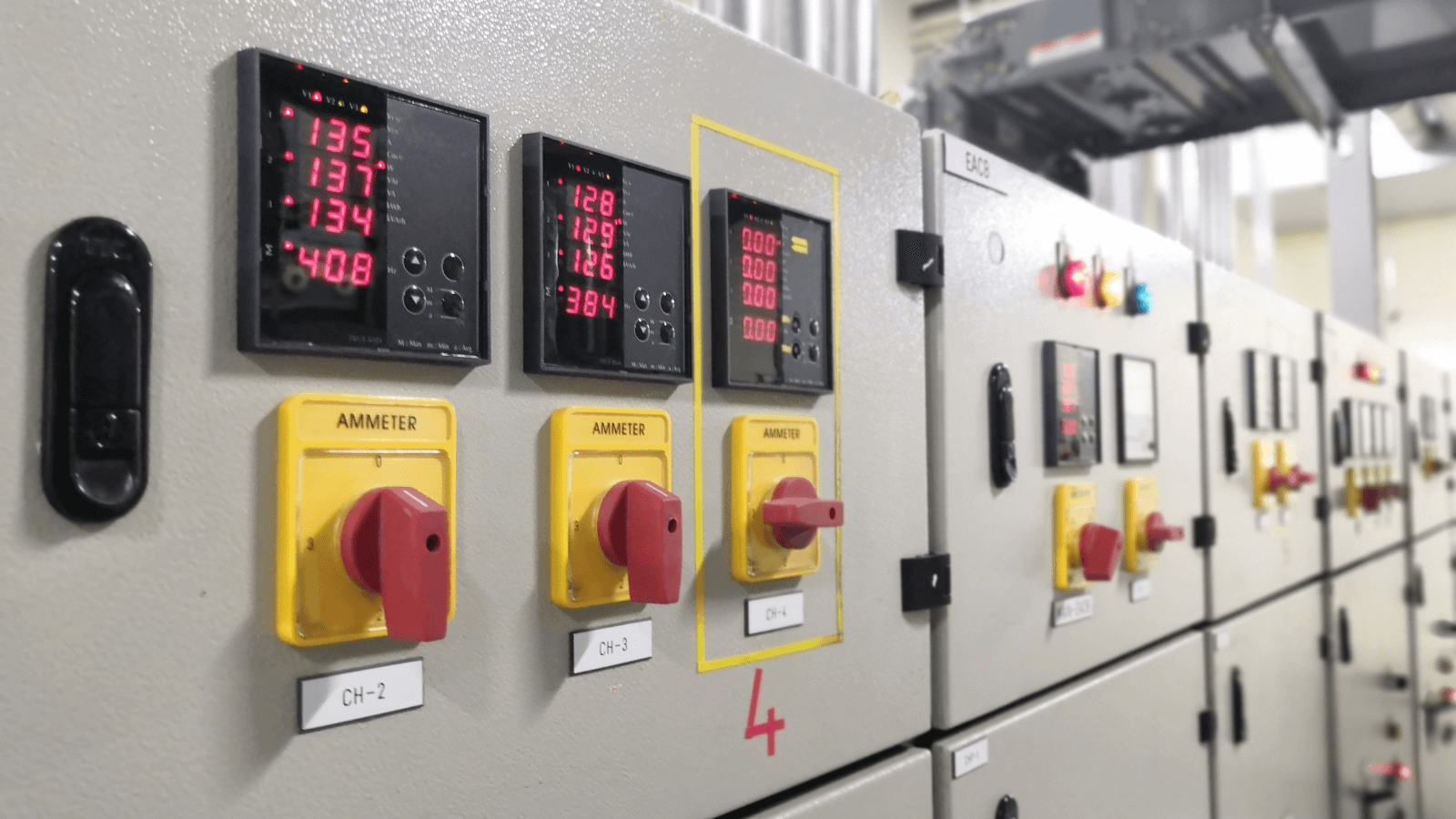

Electrical

Insulating components with excellent dielectric properties, flame resistance, and mechanical strength for various electrical systems and equipment.

Our Products Used:

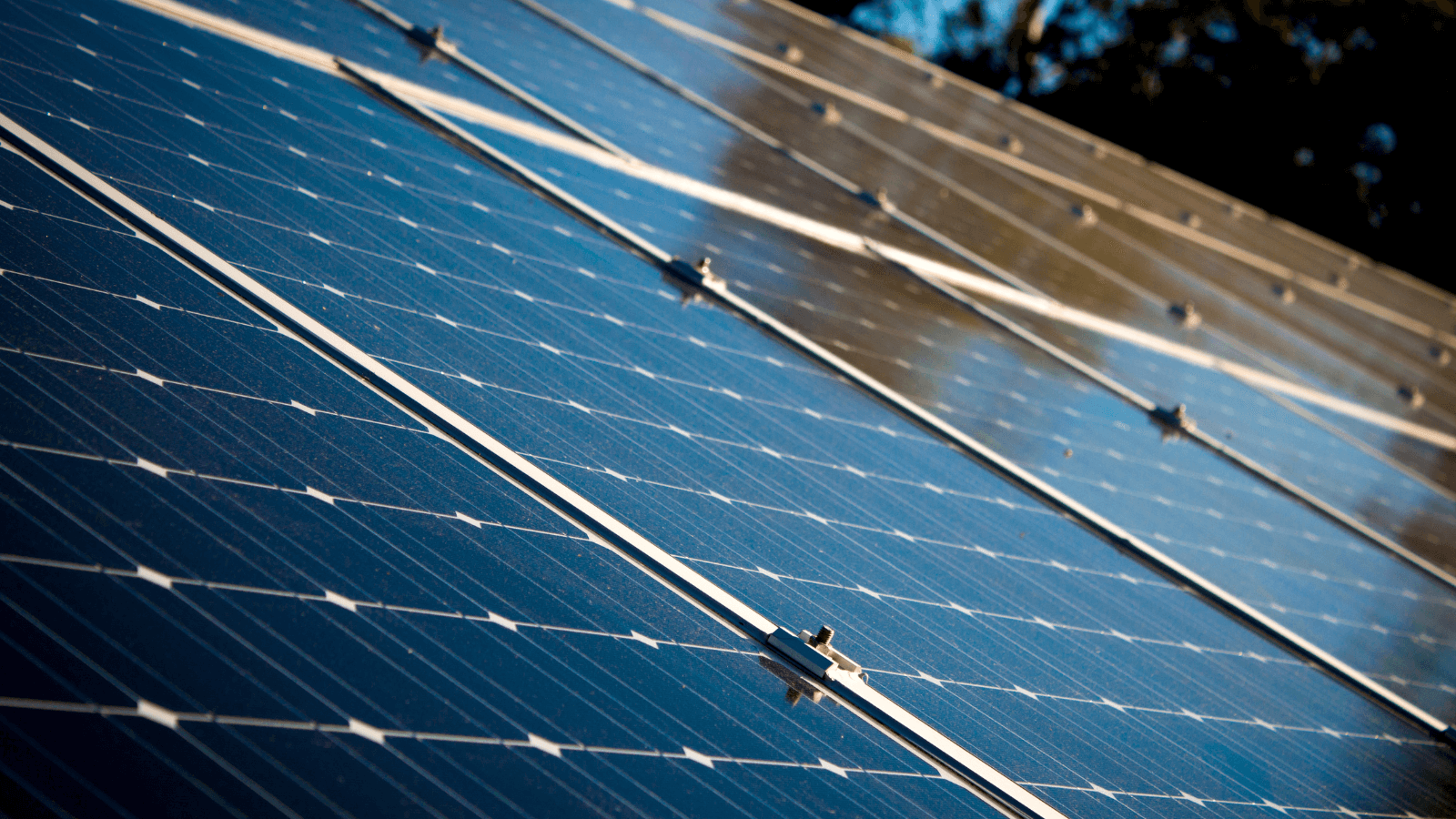

Energy

Components for renewable energy systems, power distribution, and energy storage with excellent durability and performance in harsh environments.

Our Products Used:

Construction & Infrastructure

Durable, weather-resistant components for building facades, structural elements, and infrastructure projects requiring long service life and low maintenance.

Our Products Used:

Sanitary Ware

Focuses on apps for sanitary product selection, maintenance guides, usage tracking, and hygiene management in homes, offices, and public spaces.

Our Products Used:

Building Material

Encompasses apps for building material sourcing, inventory management, quality verification, and cost control in construction and renovation projects for teams.

Our Products Used:

Public Transportation

Focuses on apps that aid route planning, ticketing, real-time transit updates, and commuter travel convenience for urban and suburban use.

Our Products Used:

Medical

Sanitary, easy-to-clean components for medical equipment with excellent chemical resistance and compliance with healthcare standards.

Our Products Used:

Other Industries

Custom composite solutions for specialty applications including marine, agriculture, aerospace, and consumer goods requiring high-performance materials.

Our Products Used:

Application Cases

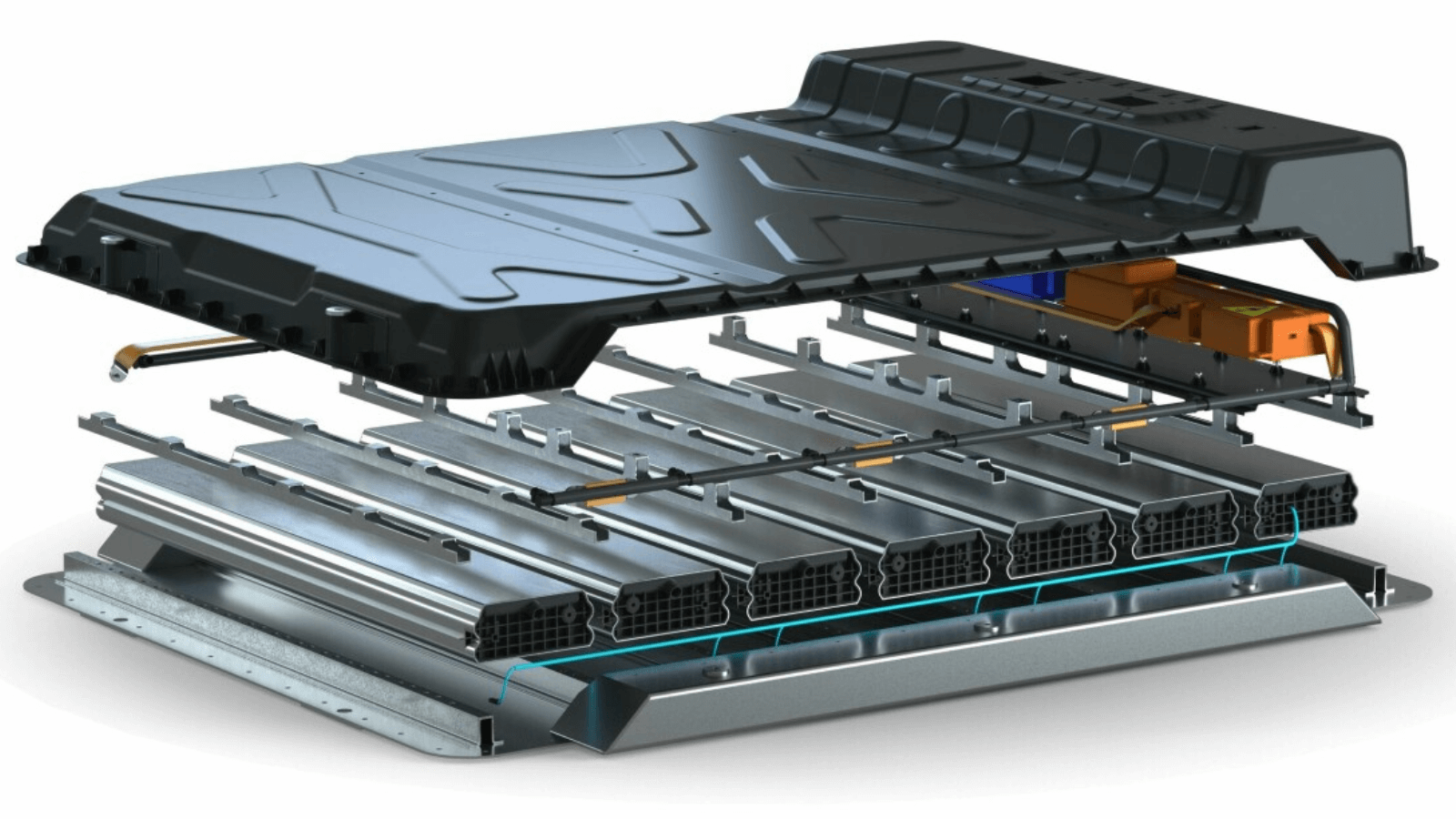

Electric Vehicle Battery Enclosures

A leading EV manufacturer implemented our flame-retardant SMC for battery enclosures, achieving 30% weight reduction compared to aluminum, excellent thermal management properties, and compliance with international safety standards.

Smart Grid Distribution Enclosures

A European utility company adopted our composite enclosures for smart grid equipment, resulting in improved corrosion resistance, better thermal performance, and 50% longer service life compared to traditional metal enclosures.

ENERGY- MOLDING SOLUTIONS

An energy storage company adopted our SMC-based battery PACK cover and end plate solutions, replacing traditional metal components. This upgrade enhanced system integration, achieved IP67 protection, increased safety, and significantly reduced costs, driving both performance and efficiency improvements.

Medical Device Housings

Medical SMC Materials-Medical Device Housings-A medical equipment manufacturer implemented our antimicrobial SMC for diagnostic device housings, meeting strict hygiene requirements, improving chemical resistance to disinfectants, and reducing weight compared to stainless steel components.

Product Features for Applications

High Strength-to-Weight Ratio

Maintains structural integrity while reducing overall weight, critical for automotive and aerospace applications.

Excellent Dimensional Stability

Consistent performance across temperature and humidity variations, essential for precision components.

Superior Surface Finish

High-quality surfaces requiring minimal preparation, ideal for visible components in automotive and medical applications.

Customizable Formulations

Tailored to specific application requirements, from flame resistance to chemical compatibility.

Thermal Resistance

Maintains performance in high-temperature environments, suitable for engine compartments and industrial equipment.

Weatherability

Resistant to UV radiation, moisture, and temperature extremes for outdoor applications.omotive, electrical, and medical.