BMC injection molding

Chinyo’s Composite Molds:The Backbone of Quality Composite Components

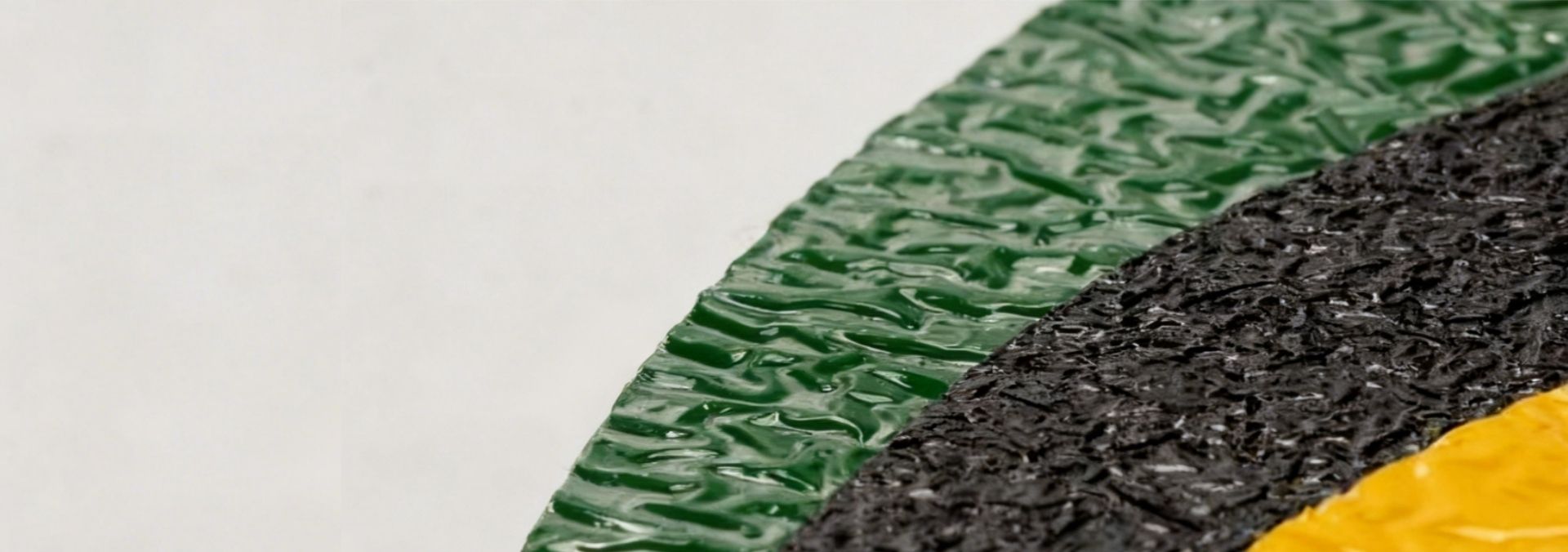

As a dedicated BMC injection molding, Chinyo’s core product line centers on precision composite tooling tailored for forming advanced composite materials. These molds serve as the critical foundation for producing consistent, high-integrity composite parts—whether for small, intricate components or large-scale structural pieces. Unlike generic molds, Chinyo’s offerings are engineered to match the unique viscosity and curing requirements of diverse composites, from carbon fiber to glass-reinforced plastics. Each mold undergoes rigorous pre-production calibration to ensure dimensional stability, directly addressing the industry pain point of inconsistent part quality. For manufacturers, this means reduced material waste and smoother production workflows, as the precision composite tooling eliminates the need for post-mold modification.

Technological Advantages:How Chinyo’s Molds Drive Value

Chinyo’s edge lies in merging advanced design with user-centric engineering, turning technical features into tangible business benefits:

Feature:Adoption of aerospace-grade aluminum alloy substrates and proprietary surface treatment.

Advantage:Resists warping under 200°C curing temperatures and maintains surface smoothness after repeated use.

User Benefit:Molds pass 1,500 hours of durability testing, extending service life by 60% and cutting replacement costs.

Feature:Integrated 3D scanning and iterative simulation in design.

Advantage:Reduces design errors by 85% compared to traditional methods.

User Benefit:Shortens tooling development cycles by 3–4 weeks, helping clients accelerate time-to-market for new products.

This focus on practical innovation solidifies Chinyo’s reputation as a BMC injection molding that prioritizes ROI.

Core Application Industries:Where Chinyo’s Molds Excel

Chinyo’s precision composite tooling addresses unique challenges across key sectors, aligning with industry-specific demands:

Aerospace:Produces lightweight, high-strength structural molds for aircraft interiors and engine components, meeting strict weight-reduction and flame-retardant standards.

New Energy Vehicles (NEVs):Supplies large-format molds for battery enclosures and body panels, enabling mass production of corrosion-resistant, energy-efficient parts.

Wind Power:Engineers molds for turbine blade roots and spars, withstanding extreme weather conditions to ensure blade longevity.

Medical Devices:Crafts ultra-precise molds for composite surgical instruments, adhering to biocompatibility and sterilization requirements.

Each application leverages Chinyo’s expertise as a BMC injection molding to turn material potential into operational excellence.

Key Parameter Overview of Chinyo’s Composite Molds

| Parameter Category | Core Specifications |

|---|---|

| Size Range | Customizable from 50mm ×50mm (small parts) to 12m ×3m (large structures) |

| Material | Aerospace-grade aluminum alloy, carbon fiber-reinforced polymer |

| Performance | Surface roughness ≤Ra 0.8μm;Operating temperature up to 220°C;Dimensional tolerance ±0.01mm/m |

| Compliance | ISO 9001:2015, IATF 16949 (automotive), AS9100D (aerospace) |

FAQ

Q:What is the lead time for custom composite molds?

A:4–8 weeks depending on size and complexity—30% faster than industry average, thanks to our simulation-driven design.Q:How do you verify mold quality before shipment?

A:Each mold undergoes 3D dimensional scanning and a 5-cycle test run with your target composite material, providing a quality report.Q:Do you offer after-sales support?

A:Yes—we provide 1-year warranty, on-site maintenance, and mold repair services to minimize production downtime.

When precision, durability, and speed matter, we are Chinyo—your reliable partner as a BMC injection molding.