Composite compound supplier

What Is Sheet Molding Compound? A Primer from Manufacturers

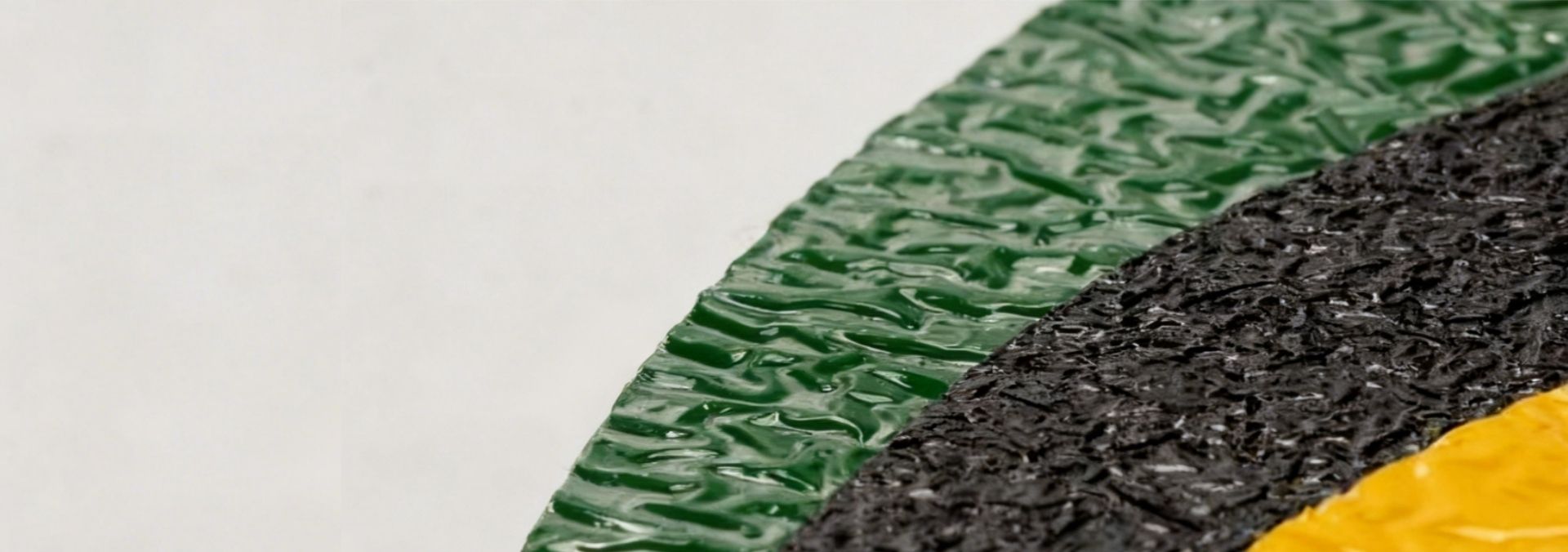

Sheet Molding Compound (SMC) is a high - performance composite material widely used in industrial production, composed of fiberglass, resin, fillers, and additives. As professional Composite compound supplier, Chinyo understands that B2B clients need materials that balance durability and processability. SMC stands out for its moldability, allowing it to be shaped into complex components with consistent quality—addressing the pain point of manufacturers struggling with rigid or low - performance alternatives. Unlike traditional metals or plastics, SMC offers corrosion resistance and dimensional stability, making it a go - to solution for long - term industrial projects. Chinyo, as one of the trusted Composite compound supplier, ensures every batch adheres to strict quality benchmarks to meet diverse industry demands.

Core Value &Technological Advantages of Chinyo’s SMC

For Composite compound supplier, technological precision directly translates to user value. Chinyo’s SMC solutions are built on three key features, each delivering clear advantages and benefits:

Low - shrinkage formulation:This feature ensures components maintain tight tolerances (±0.1mm). The advantage is reduced post - molding processing, and the benefit for users is a 30% cut in production time and labor costs.

High - fiber loading technology:With 25 - 35% fiberglass content, the material gains enhanced structural strength. It has passed 1,500 hours of salt spray testing, so the advantage is superior corrosion resistance, and the benefit is a 50% extension in product lifespan for outdoor or harsh - environment applications.

As leading Composite compound supplier, Chinyo’s tech innovations turn material features into tangible cost savings and performance gains for clients.

Key Application Scenarios for SMC from Manufacturers

Composite compound supplier like Chinyo tailor SMC to serve core industrial sectors, addressing unique industry needs:

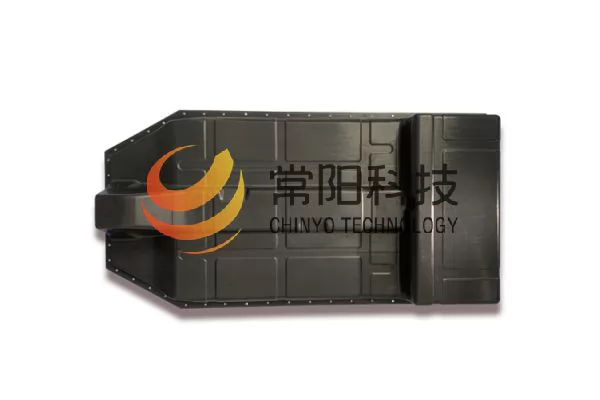

Automotive industry:Automakers need lightweight yet strong components to improve fuel efficiency. Chinyo’s SMC is used for battery housings and body panels, reducing vehicle weight by 20% while meeting crash safety standards.

Electrical &electronics:Clients require flame - retardant and insulating materials. SMC components for switchgear and transformer enclosures pass UL94 V - 0 flame tests, minimizing fire risks in electrical systems.

Renewable energy:Solar and wind industries need weather - resistant parts. Chinyo’s SMC solar panel frames and wind turbine components withstand extreme temperatures (-40°C to 120°C), ensuring 25+years of reliable operation.

These applications highlight how Composite compound supplier bridge material capabilities with industry - specific demands.

Core Parameter Overview of Chinyo’s SMC

As responsible Composite compound supplier, Chinyo provides transparent parameter information to support B2B procurement decisions:

| Parameter Category | Key Details |

|---|---|

| Size &Form | Sheet thickness:2 - 6mm;Roll width:1000 - 1500mm (customizable);Weight per roll:200 - 500kg |

| Material Composition | Unsaturated polyester resin, alkali - free fiberglass, calcium carbonate filler, low - shrinkage additive |

| Performance Metrics | Tensile strength:≥60MPa;Heat resistance:Continuous use at 120°C;Water absorption:≤0.5% after 24 - hour immersion |

| Compliance Certifications | ISO 9001:2015 (quality management);IATF 16949 (automotive industry);UL94 V - 0 (flame retardancy) |

FAQs

Q:What is the lead time for bulk SMC orders?

A:For orders above 50 tons, lead time is 7 - 10 working days—faster than the industry average of 14 days—ensuring your production line stays on schedule.

Q: Can Chinyo customize SMC for specific color or hardness needs?

A:Yes, we offer 10+standard colors and hardness adjustments (Shore D 70 - 85) to match your product design requirements, no minimum order for customization.

Q: How does Chinyo ensure consistent quality across batches?

A:Each batch undergoes 8 - point quality checks, including tensile strength and shrinkage testing, with test reports provided for every delivery.

As professional Composite compound supplier, we prioritize your production efficiency and product reliability. We are Chinese. Contact Chinyo today to discuss your SMC needs and get a tailored quote.