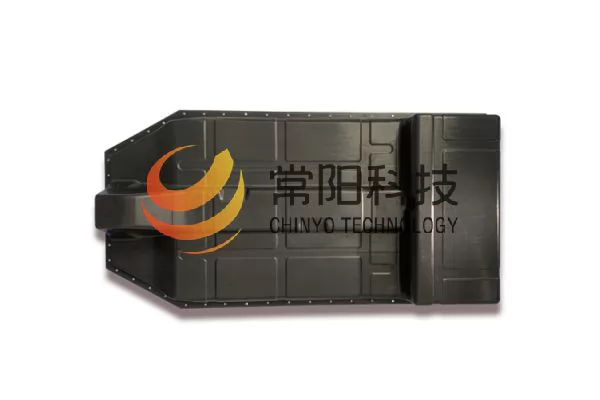

Custom composite mould

We are Chinyo! Ready for custom, high-precision Custom composite mould solutions for automotive, energy, and railway sectors —contact us now to request samples, technical consultation, or a quotation.

Why Chinyo is the Preferred Custom composite mould

Chinyo combines over ten years of experience with integrated services —from material formulation to mold design and high-precision molded components —delivering improved part performance, lower supplier complexity, and faster time-to-market for regulated and high-volume programs. Our R&D iterates resin systems for flame retardancy, insulation, and weight reduction while maintaining manufacturability at scale.

Experience &Expertise as an Custom composite mould

Chinyo’s decade of hands-on experience ensures predictable shrinkage, controlled cure, and consistent mechanical properties. Our engineers provide DFM guidance and lab-backed prototyping so customers avoid costly redesigns during scale-up.

End-to-End Customization as an Custom composite mould

We tailor formulations, fiber content, additives, and tooling to match product specs —delivering parts ready for validation rather than piecemeal components.

Quality &Compliance as an Custom composite mould

Material inspection, mechanical testing, thermal and electrical verification, and traceability ensure parts meet industry and client standards for automotive and rail.

Manufacturing Capabilities of Chinyo as an Custom composite mould

Chinyo operates mixing, cutting, and automated compression molding lines plus finishing —supporting prototyping and full-scale production. We control cure cycles, pressure and handling to minimize defects and achieve consistent surface aesthetics required for interior/exterior automotive parts and safety-critical energy components.

Advanced Mixing &Formulation as an Custom composite mould

Precise mixing delivers consistent viscosity and fiber dispersion, improving mold fill for thick sections and complex geometries.

Precision Molding Lines as an Custom composite mould

Automated presses and handling produce repeatable cycles, high-quality surfaces, and tight tolerances;secondary operations (machining, insert molding, painting) let us deliver assemblies.

Engineering Advantages Chinyo Offers as an Custom composite mould

Chinyo turns material science into practical product advantages. We provide application engineering —matching resin systems to requirements like impact resistance, EMI shielding, and thermal stability —and run trade-off studies to meet cost, weight, and safety targets quickly.

Design for Performance as an Custom composite mould

We optimize fiber orientation, section thickness, and geometry to reach stiffness and impact goals while avoiding warpage and unnecessary weight.

Testing &Validation as an Custom composite mould

Mechanical, thermal, environmental, and lifecycle tests validate long-term performance for automotive and railway standards.

Commercial &Supply Advantages from Chinyo as an Custom composite mould

Chinyo’s integrated supply model (compounding →tooling →molding →finishing →logistics) reduces vendor overhead, shortens lead times, and lowers total cost of ownership. We offer scalable production planning, buffer inventory, and export-ready documentation for global programs.

Cost Efficiency as an Custom composite mould

Process optimization reduces scrap and cycle time;consolidated services lower logistics and vendor management costs.

Supply Reliability as an Custom composite mould

Production planning, traceable batches, and scheduled shipments support JIT and program ramp-ups without quality compromise.

SMC vs BMC

| Property / Use | SMC | BMC |

|---|---|---|

| Typical form | Sheet molding compound | Bulk molding compound (paste) |

| Best for | Large structural panels, thicker parts | Smaller, complex shapes with fine detail |

| Fiber content | Higher (longer fibers) | Lower (shorter fibers) |

| Surface finish | Good (with veils) | Very good (molded detail) |

| Typical industries | Automotive structural, energy housings | Electrical components, housings |

FAQs

Q: What industries does Chinyo serve?

A: Automotive, energy, and railway —structural panels, housings, insulators, and aesthetic components.

Q: Can Chinyo customize SMC formulations?

A: Yes —resin chemistry, fiber content, additives, and tooling are tailored to requirements.

Q: Do you provide tooling and molding together?

A: Yes —integrated mold design, tooling, compression molding, and finishing services.

Q: How long has Chinyo been an Custom composite mould?

A: Chinyo has over ten years of experience in SMC/BMC composite solutions.

Conclusion

Chinyo is a full-service Custom composite mould combining material science, precision molding, and supply reliability to serve automotive, energy, and railway customers. With 10+ years of experience, integrated capabilities, and engineering support, Chinyo reduces development risk and delivers production-ready parts that meet stringent performance and regulatory needs. Contact Chinyo to start your program.